1. Industrial Thermography/Thermal Imaging Inspection

Faults can be fixed before the Breakdown

Thermography plays an important role within the petrochemical, chemical, and power generation industries.All Industries has to carry out predictive maintenance inspections to make sure of smooth running. Within a refinery complex there are a number of different plants that carry out a specific function and process.In each plant or industry multitude of equipment from electrical to mechanical, to steam generation and steam powered, to hydraulic.

Specialized Thermography in Oil & Gas Industries:

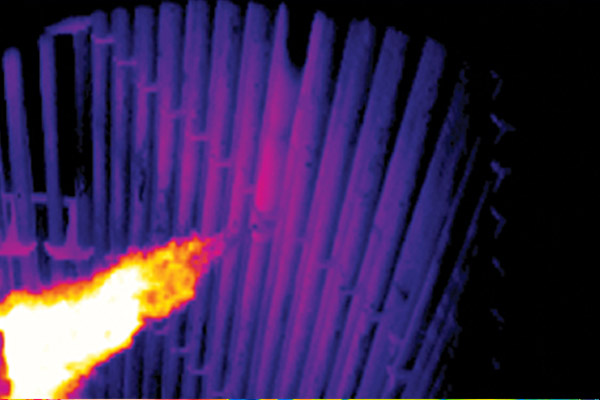

● Finding & knowing the length of leak in suspected pipeline or suspected area.

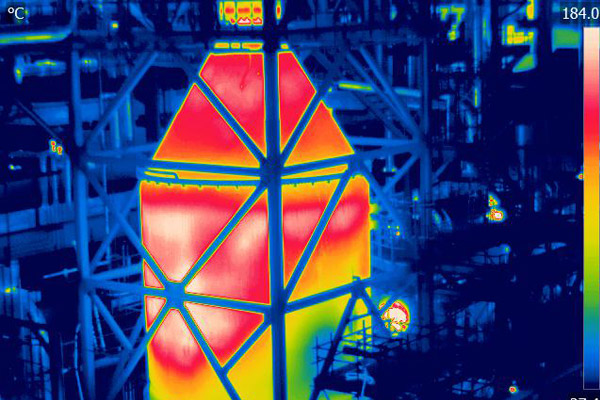

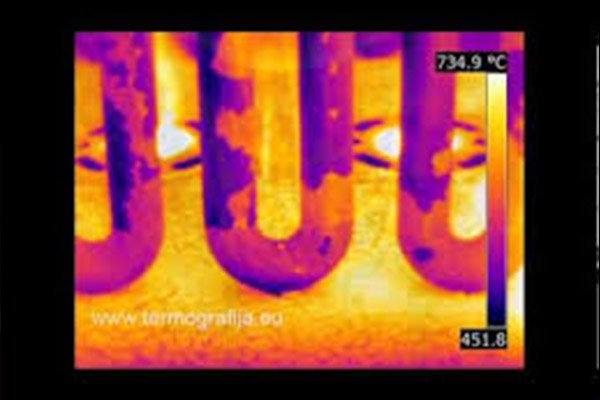

● Inspection of Reactors, Burners, Piping, Heat Exchangers, Process Gas Boilers and Furnace walls for insulation thickness & damages.

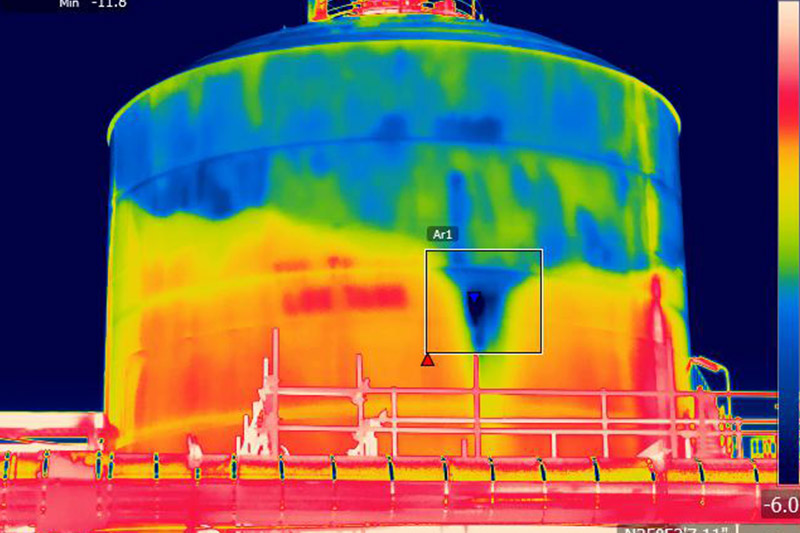

● Inspection of Cold storage tanks for possible cold spots.

● Inspection of View Ports or inspection windows of Furnace to study & find the air leak which can reduce the efficiency of Furnace Chamber.

● Studying the heat flow on across the pipe.

● Finding leaks in safety valves, etc..

2. Furnace Inspection/Heater/Tube Inspection :

TIS offers furnace inspection using advanced infrared cameras, for example GF 309.The FLIR GF309 is designed for high temperature industrial furnace applications. These infrared cameras are ideal for monitoring all types of furnaces, heaters and boilers, particularly in the chemical, petrochemical and utility industries. Custom-built to see through the flames, the FLIR GF309 also features a detachable heat shield designed to reflect heat away from the camera and camera operator, providing increased protection.

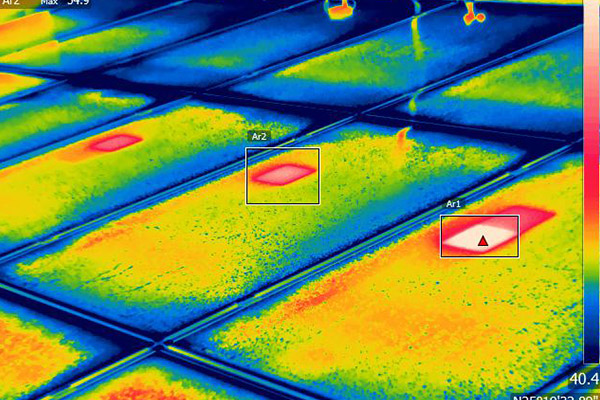

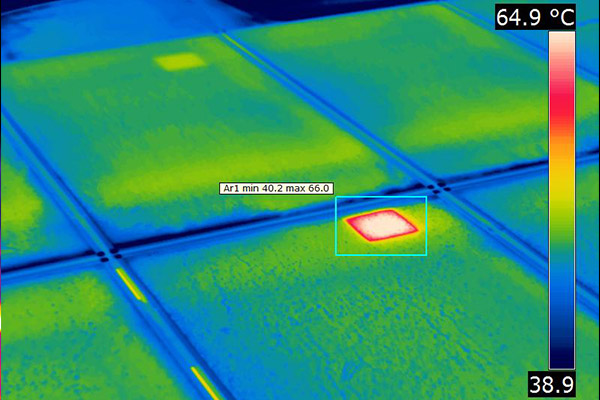

3. Solar Panels Themrography Survey/Inspection

The thermographic analysis is a useful tool for on-site monitoring of building integrated photovoltaic systems. Thermography survey shows the abnormalities, which can be investigated concerning either the panel material itself or its function.

Thermal imaging cameras look for panel hotspots. Overheated cells can damage the casing material and cause delamination.

The solar panel hot spots create two issues:

● Fall in overall power production since cells consume power instead of producing.

● Power consumption continues to heat up cells and affect the production of neighboring cells.

● Defective cells lead to considerable loss of performance from the system

● A temperature increase of 10 °C above the operating temperature recommended by the manufacturer can lead to a 50 % shortening of its lifetime

● Defective cells can lead to an enormous heat development, and thus to the danger of fire.

4. Gas Leakages Inspection (LDAR):

Many industrial gases and chemical compounds are invisible to the naked eye. Optical imaging using thermal cameras for Gas Imaging, offer a number of benefits compared to traditional “sniffers” because they scan a broader area much more rapidly and in areas that are difficult to reach. Infrared displays a leak as a plume of vapor in the infrared image. Once a leak is found, from a safe distance, we use our Toxic Vapor Analyser (TVA) to quantify the concentration.

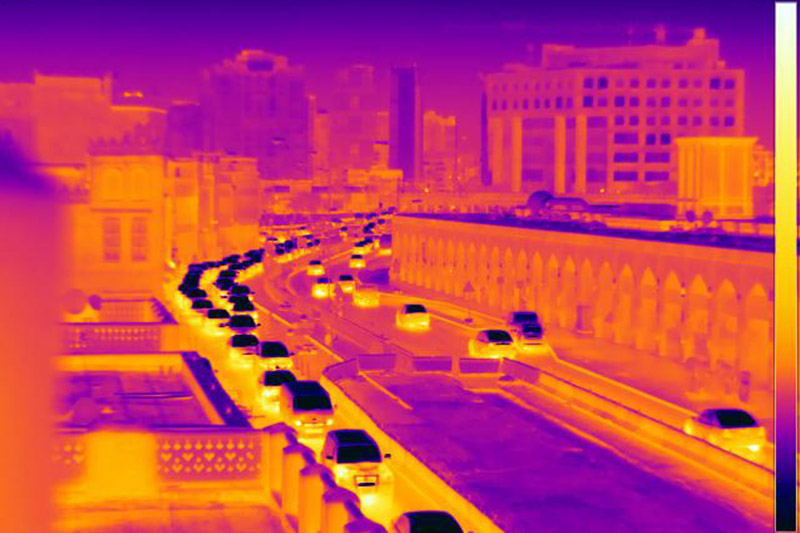

5. Environment Thermography Survey :

6. Medical Thermography:

Supply of IR Cameras & Automation System

TIS is an authorized dealer for FLIR optical gas imaging cameras (GF Series) and Automation Cameras (A Series) in the State of Qatar. We offers ITC certified trainings for your personnel in terms of technical and practical knowledge for the effective usage of those cameras.

FLIR automation series thermal imagers offer affordable, fully integrated thermal imaging and measurement solutions for applications such as process development and optimization, industrial process monitoring, product verification, quality assurance, safety applications and much more. An infrared camera can detect even small temperature differences in most operating conditions, including when there is smoke, fog or steam involved in the measurement situation.

System Integration: We are associated with one among the leading FLIR approved System Integrator having vast experience in the field of Industrial Automation known as IMC Service, Italy for configuring thermal cameras according to the clients requirements and up-to-date technology.